Air conditioning, fuel injection, electric fans and other modern amenities are becoming the norm in hot rods. All of these systems are designed to enhance performance or are simply creature comforts, but one area that must be addressed when updating your hot rod is the charging system.

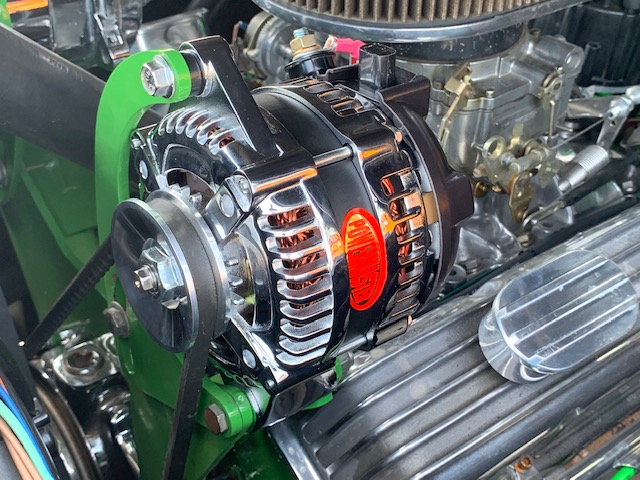

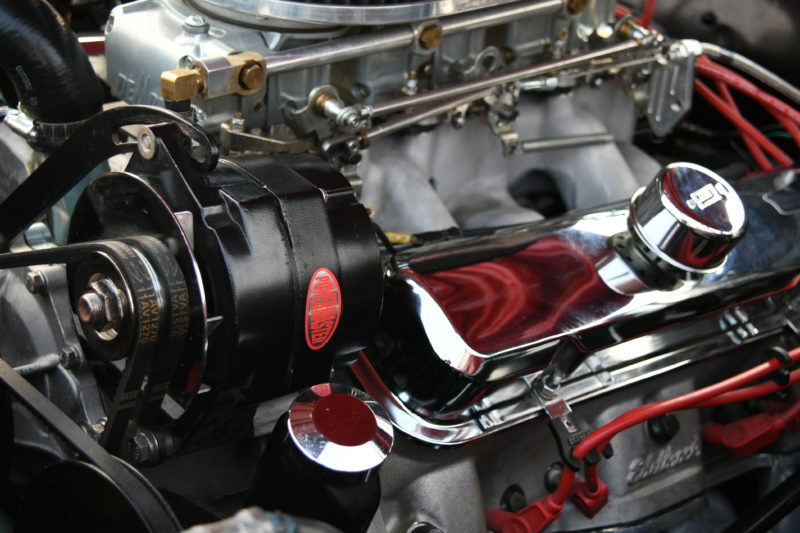

To learn more about selecting the best alternator for your application, we went to Powermaster Performance. The West Chicago, Illinois-based company has been designing and building alternators for the performance aftermarket for 25 years.

Powermaster explained that the most important step in choosing an alternator is to review the current demands from the electronic components on your car. For instance, a typical set of headlights and tail lamps use 5–6 amps (up to 10-amps for a Halogen and HIDs), a single electric fan can pull 30–40 amps (twice that with a twin system), air conditioning up to 20 amps, fuel pump, air compressors for suspensions, power windows, etc.

When you start to look at each circuit, you’ll see that the numbers add up quickly and can easily out-perform your factory alternator. Choose one that exceeds your demands and look at both the idle output as well as peak. Remember, your engine spends a lot more time at idle and lower rpm so idle rpm output is imperative when choosing a new alternator. Powermaster's new line of HPR Alterantors have been engineered to deliver high idle output as well as cruising rpm. In fact, the small case HPR idles at over 145 amps while the larger, late model HPRs put out 195 amps - and are direct bolt-in upgrades!

Another consideration is the decision to go with a one-wire alternator versus an OEM-style connection (often regarded as 3-wire connection). The jury on this one is strongly divided, but the major difference is how the alternator starts to charge. With an OEM-style connection, the alternator is turned on, or excited, by receiving a 12-volt signal from the ignition switch. As soon as the engine starts, the alternator is charging.

One-wire alternators, known as self-exciting, have an internal sensing circuit that turns on the charging circuit once it reaches a certain rpm. Powermaster’s one-wire alternators easily begin charging at 800-1000 rpm and continue charging even at lower rpm. Less wiring for an overall easier and cleaner installation.

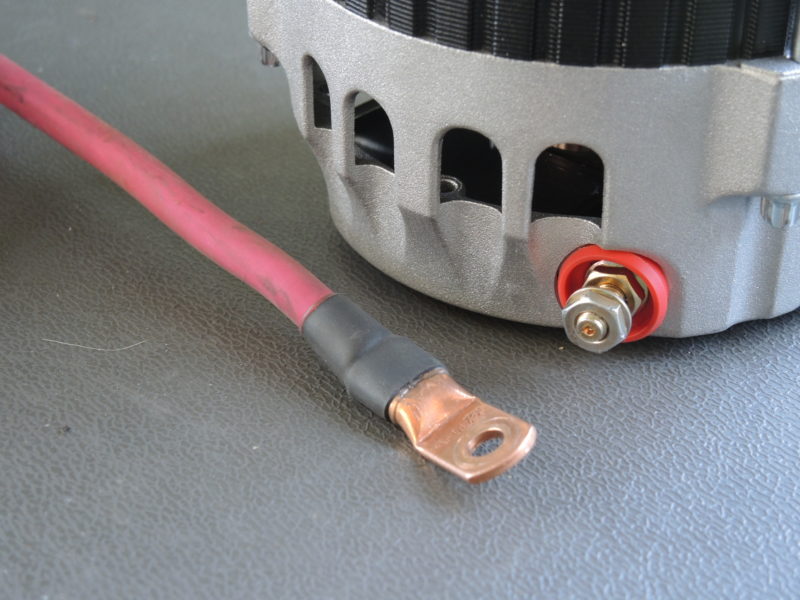

No matter which alternator you select, one of the most important installation tips to consider is the gauge and length of the charge wire. Remember, stock wiring was designed to handle 40–50 amps on a good day, and if you start pulsing high current through old, original wiring, things are not going to go well. High-output alternators require a path to the battery positive terminal and the charge wire must be large enough to make sure the electrons get there effectively. Powermaster offers a number of different gauge and length charge wires to fit any application.

The alternator and charging system are going to determine how well anything electrical operates on your car. Proper current and output levels will also ensure the longevity of these accessories so make sure you have an alternator that can keep up with your car’s requirements.

Powermaster Performance - www.powermasterperformance.com